|

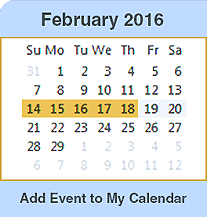

Preview these special sessions planned for the TMS 2016 Annual Meeting & Exhibition.

TMS 101: Fundamentals of TMS

Sponsored by the TMS Professional Development Committee

Date: Sunday, February 14, 2016

Time: 5:00 p.m. to 5:30 p.m.

Location: Music City Center, 208A

Presenters:

Jeffrey W. Fergus

Jeffrey W. Fergus

Auburn University

Clarissa Yablinsky

Clarissa Yablinsky

Los Alamos National Laboratory

Want to get more involved in TMS, but don’t know where to start? Attend TMS 101: Fundamentals of TMS. This half-hour presentation will provide a brief overview of how TMS works and a concise, practical explanation of how you can get more involved in the society’s activities. Led by experienced TMS volunteers, TMS 101 will help you to take advantage of the many networking and professional development opportunities within the organization.

This session is open to all TMS2016 attendees but will be especially valuable to new members, international members, and graduate students.

All participants are invited to continue networking at the TMS2016 Opening Celebration immediately following this session. Here, you will be encouraged to further discuss opportunities to participate in TMS activities, such as joining a TMS technical committee or contributing to programming and publications.

TMS2016 Light Metals Keynote Session

Pushing Boundaries—Innovative Thinking in Light Metals Production

Date: Monday, February 15, 2016

Time: 8:30 a.m. to 10:30 a.m.

Location: Music City Center, Room 202

Presenters:

"Aluminum: Modern, Innovative, Attractive"

Martin Iffert, CEO Trimet Aluminium SE

Abstract

The history and future will be presented for modern Additive Manufacturing (AM), also known as 3D Printing. The technology, divided into seven categories by ASTM, dates to the 1980s, although precursor processes and AM "prehistory" date to the 1950s and the previous century, respectively. A rationale will be presented for the use of AM processes in lieu of conventional manufacturing processes. Two requirements for parts under consideration for AM are complex geometry and low production runs. Current sectors using AM illustrate the results. A survey of materials for AM will be provided. Some consideration will be presented respecting where AM technology is headed.

About the Presenter

Martin Iffert studied electrical engineering at RWTH Aachen University and began his professional career in 1994 as a trainee at ALUMINIUM Essen GmbH, a TRIMET company, and subsequently became operations manager, production manager, electrolysis manager, and plant manager.

In 2007, he earned his doctorate from the University of New South Wales. Alongside his professional responsibilities he completed the MBA program at the IMD Business School in Lausanne.

Iffert has published numerous technical papers and spoken at international conferences. Noteworthy achievements include expanding the electrolysis capacity of the Essen plant, recommissioning the Hamburg plant, and taking charge of and integrating the production plants in Saint-Jean-de-Maurienne and Castelsarrasin plus the electrolysis plant in Voerde.

Iffert has been a member of the TRIMET Aluminium SE executive board since March 1, 2009, and was appointed chairman of the executive board on October 1, 2011. In addition, he has been president of TRIMET France SAS since December 16, 2013.

"Lightweighting: What is the Future for the Automotive Industry?"

Stephane Delalande, Deputy Scientific Director, PSA Peugeot Citroën

Abstract

In this lecture, we will present the relation between the modification of mobility patterns and the need for lightweighting for automobiles. For many years, to improve security and comfort, car manufacturers have increased the weight of their vehicles. However, due to environmental concerns, numerous countries have implemented their own CO2 emission rules. Currently, many different strategies exist to address these emission reduction objectives. One important way is the mass reduction of automobiles, in particular, for hybrid and electric cars. There are three main ways to do so, of which two of them are using materials with a lower density or materials with better mechanical properties. We will investigate the balance between both solutions from mass production to premium sport car manufacturing. This will aid us in describing the development and design of vehicles in the future.

About the Presenter

Stephane Delalande has a Ph.D. in Materials Science from the University Pierre et Marie Curie in Paris. As the Deputy of the Scientific Director, he is in charge of all scientific programs and partnerships with universities and institutional research centers. In addition, he is responsible for the development of PSA Peugeot Citroën’s scientific collaborations in the United States and the materials expert for PSA Group.

Delalande has worked on projects concerning the introduction of lightweight materials in cars—aluminum, magnesium, and composites. This included study of the surface treatment, rules of conception, and joining techniques for these materials. He is the leader of the Material Expert Group of all European Car manufacturers with relationships to European Council.

Delalande is currently a visiting associate at the California Institute of Technology.

Magnesium Technology Keynote Session

Date: Monday, February 15, 2016

Time: 8:30 a.m. to 2:30 p.m.

Location: Music City Center, Room 204

Planned Presentations:

- "Challenges for Implementation of Magnesium into More Applications"

Presenter: Karl Kainer, Helmholtz-Zentrum Geesthacht, Germany

- "Development of Magnesium Alloys for High Speed Trains in China"

Presenter: Eric Nyberg, Pacific Northwest National Laboratory, USA

- "Korea’s R&D Activities Towards the Application of Wrought Mg Alloys"

Presenter: Nack J. Kim, POSTECH, Korea South

- "Mg Alloys Strengthened by Complex Phases"

Presenter: Alok Singh, National Institute for Materials Science, Japan

- "Developments in High Magnesium-Content Bulk Metallic Glasses and Future Possibilities"

Presenter: Kevin Laws, University of New South Wales, Australia

- "A Perspective: Potential Growth in the Global Magnesium Industry – Where is our Research Leading Us?"

Presenter: Martyn Alderman, Magnesium Elektron, Great Britain

Student-Run Symposium: Transforming the Diversity Landscape

Date: Monday, February 15

Time: 8:30 a.m. to 4:00 p.m.

Location: Music City Center Room 104A

This symposium builds on the first TMS Summit on Diversity in the Minerals, Metals, and Materials Professions (DMMM1). Organized by graduate students Wennie Wang, Natalie Larson, and David Hwang (pictured, left to right) of the University of California, Santa Barbara, the symposium seeks to address challenges of the current diversity landscape in science, technology, engineering, and mathematics (STEM) fields and to provide concrete actions to promote diversity.

Presentations will include:

- "Diversity Beyond the Numbers: Fostering and Sustaining Diversity in the Minerals, Metals, and Materials Professions"

Elizabeth Holm, Carnegie Mellon University

- "Diversity Leads to Innovation"

Cammy Abernathy, University of Florida

- "Understanding and Addressing the Patterns of Bias in STEM Environments"

Kristen Constant, Iowa State University

- "Securing the Future of American Public Research Universities by Increasing the Number of Under-reprsented Minorities in STEM"

Aeriel Murphy, University of Michigan

- "The Impact of Coaching, Mentoring, and Sponsorship on Diversity"

Kathleen Chou, The Boeing Company

- "PEERs: Educating and Empowering Student Change Agents in the University of Washington’s College of Engineering"

Alexis Nelson, University of Washington

- "JSU ADVANCE: Bias Awareness Strategies to Affect University Policies"

Thomas Hudson, Loretta Moore, Janice Lassiter-Mangana, Jackson State University

- "How to do Diversity at the PhD Level in STEM: Lessons and Tools from the Fisk-Vanderbilt Bridge Program"

Keivan Stassun, Vanderbilt University

Panel of Past TMS Presidents: Transforming the Diversity Landscape

Past TMS presidents Dan Thoma, Bob Shull, Brajendra Mishra, Wayne Jones, Tresa Pollock, and Diran Apelian will share their perspectives on transforming the diversity landscape in STEM.

For more information on this symposium and planned presentations, visit the symposium’s page on ProgramMaster.

|

REWAS 2016 Plenary Session:

REWAS 2016 Plenary Session:

Materials Matter: Deriving Value from Resource Recovery at Multiple Materials Scales

Date: Tuesday, February 16, 2016

Time: 8:30 a.m. to Noon

Location: Music City Center, Room 104B

This special plenary session will be a highlight of the REWAS2016 technical program. REWAS is a trans-disciplinary conference—held as part of the TMS 2016 Annual Meeting & Exhibition—where materials professionals can exchange ideas with those in other research fields and stakeholders to synergistically define the way toward a resource-efficient industry and society. The following invited speakers will deliver their

presentations and participate in panel discussions

with the audience:

- "Gold’s Evolving Role in the Circular Economy"

Trevor Keel, Consultant to the World Gold Council

- "Automotive Recycling Innovations in Aluminum"

Sil Colalancia, Novelis

- "Digitalizing the Circular Economy -System-Integrated-Material-Production"

Markus Reuter, Helmholtz Institute Freiberg for

Resource Technology, and 2016 TMS Extraction &

Processing Division Distinguished Lecturer

- "Industrial Symbiosis and Materials Management: Physical Resource Sharing Among Proximate Firms"

Marian Chertow, Yale School of Forestry &

Environmental Studies

- "Water at the Heart of the Circular Economy"

Edwin Piñero, Senior Vice President for Sustainability and Public Affairs, Veolia North America

- "Environmental Impacts of Additive Manufacturing"

William P. Flanagan, Director, Ecoassessment

Center of Excellence, General Electric Company

2016 Bladesmithing Symposium Keynote Presentation

Connections: Superplasticity, Damascus Steels, Laminates, the Giza Pyramid, and Carbon Dating

2016 Bladesmithing Symposium Keynote Presentation

Connections: Superplasticity, Damascus Steels, Laminates, the Giza Pyramid, and Carbon Dating

Jeffrey Wadsworth, Battelle

Date: Tuesday, February 16, 2016

Time: 8:35 a.m.

Location: Music City Center, Room 104A

In the mid-1970s, a race was underway to develop superplasticity in steels. This keynote presentation will describe how that research program led to a series of investigations into historical materials starting with Damascus Steels. The archaeometallurgy of swords and knives will be discussed starting with the early development of wood, bone, horn, and stone knives and evolving

to the present time where modern Bladesmiths use an astonishing range of sophisticated materials and manufacturing methods.

About the Bladesmithing Symposium

The 2016 Bladesmithing Symposium builds upon the phenomenal success of the Bladesmithing Competition held at TMS2015 last year and serves as a bridge to the next Bladesmithing Competition planned for TMS2017 in San Diego, California. Students and student teams will present their work associated with or inspired by the 2015 Bladesmithing Competition.

|

Materials Innovation Keynote Session:

Multidisciplinary Materials Design Optimization Under Uncertainty

Date: Wednesday, February 17, 2016

Time: 8:30 a.m.

Location: Music City Center, Room 207B

This special keynote session is organized by the

TMS Materials Innovation Committee and will

feature the following presentations:

- "Morphing the Design Box: New Design Paradigms Enabled by Additive Manufacturing"

Rick Barto, Lockheed Martin

- "Model-Based Materials Definitions for Design and

Structural Analysis"

David Furrer, Pratt & Whitney

- "Statistical Rigor Versus Statistical Confidence in

the Optimal Design of Materials"

Michael McKerns, California Institute of

Technology

- "A Set-Based Approach for Hierarchical Materials

Design"

Carolyn Seepersad, University of Texas at Austin

TMS2016 Acta Materialia Symposium

Date: Wednesday, February 17, 2016

Time: 3:30 p.m.

Location: Music City Center Room 103C

This special symposium will honor two TMS members who will be accepting their prestigious Acta Materialia Awards at the TMS 2016 Annual Meeting & Exhibition. The session will include presentations by the award recipients:

Sungho Jin

"Structural Control for Enhanced

Functional Materials"

Sungho Jin

"Structural Control for Enhanced

Functional Materials"

Recipient of the 2016 Acta Materialia Gold Medal

Professor Emeritus, University of California, San Diego

2000 TMS Fellow

Julie Schoenung

"Even ‘Green’ Technologies Create

Environmental Impact:

A Case Study Perspective"

Julie Schoenung

"Even ‘Green’ Technologies Create

Environmental Impact:

A Case Study Perspective"

Recipient of the 2016 Acta Materialia Hollomon Materials and Society Award

Professor, University of California, Irvine

Abstract

Significant efforts have been made to advance technologies that provide a reduction in the energy demands of consumers. For instance, bulbs made with light emitting diodes (LEDs) have been demonstrated to last longer and save substantial energy when compared to conventional incandescent lighting. Thin film solar cells provide improved efficiencies over conventional silicon based technologies, both of which offer energy from renewable sources rather than from fossil fuels. In the consumer electronics arena, recycling at end-of-life has become essential to recover valuable materials and ensure proper disposal of toxic substances. Yet all of these technologies, thought to be advancing the state of the art in sustainable, green design require the utilization of resources (materials and energy) and create potential environmental impacts (both human and ecological), as do all product fabrication processes. This presentation will review a series of case studies on these technologies highlighting the various types of impacts associated with them, in an effort to guide future development of sustainable technologies such that they require less resource input, generate less environmental impact and/or use fewer toxic substances.

Abstract

Modern technologies benefit greatly from the discovery and application of new functional materials and associated devices. Functional materials encompass a broad spectrum of materials having useful properties including mechanical, electronic, optical, magnetic, biological, or energy-related properties. It is important to be able to control the properties, for example, by altering the microstructures/nanostructures or by taking different materials processing routes. In this presentation, some example functional materials R&D projects will be described with emphasis on microstructural control to impart unique or enhanced properties, and their potential technical applications will be discussed.

|