TMS 2017 Course Offerings

Full Day Events

Emerging Electronic Interconnect Materials and Processing for Advanced Packaging Technology Workshop

Refractory Linings Used in Aluminum Production

Half-Day Morning Events

Hands On: Interactive Materials Data Visualization and Selection Tools for Research and Teaching Workshop

Hands On: New Demos and Activities to Engage Students in Materials Science and Engineering Workshop

Managing Sulfur in Cokes, Anodes, and Smelter Potline Exhaust Gases Course

Half-Day Afternoon Events

Additive Manufacturing Materials and Processes Workshop

Emerging Technologies that are Poised to Change the Aluminum Industry Workshop

How Carbon Materials are Used in Aluminum Production Workshop—an Introduction for Non-Technologists

Introduction to Atom Probe Tomography Workshop

|

| Managing Sulfur in Cokes, Anodes, and Smelter Potline Exhaust Gases Course |

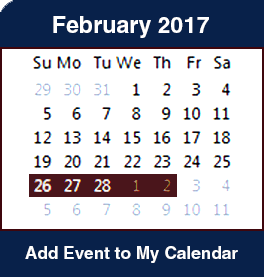

| When | Sunday, February 26, 2017 • 8:30 a.m. to Noon |

| Where | San Diego Convention Center |

| Sponsorship | TMS Light Metals Division (LMD) and Aluminum Committee |

| Instructors | Stephan Broek, Hatch Ltd.; Les Edwards, Rain CII Carbon LLC; and Barry Sadler, Net Carbon Consulting Pty Ltd. |

| Flyer |

View / Download View / Download |

SCOPE

Emissions of sulfur from coke calciners and smelters are more and more scrutinized. In this course we will look at the sulfur in the petroleum cokes, how sulfur behaves in the calciner, and what calciners do to abate sulfur emissions. Then, we will look at the production of anodes and how the sulfur behaves in the baking furnace. The formation of SOx and if it can be scrubbed in the ABF will also be covered, as will the presence of sulfuric acid in the furnace off gases. After this, we will look at how the sulfur behaves in pots. For abatement in smelters we will review in detail the current status of applicable SO2 scrubbing technologies. After the course, attendees will have a good understanding of the full cycle of sulfur from coke to GTC stack and be up-to-date to manage sulfur emissions.

WHO ATTENDS?

Environmental specialists, plant engineers, raw materials technologists, lead operating staff, EHS professionals, key technologists from supplying companies, environmental regulators and authorities, and researchers will all benefit from attending this course.

TOPICAL OUTLINE

- Sulfur in Cokes and Calcining

- Source of Sulfur in Cokes

- Trends

- Impact of Sulfur Levels on Coke Properties and Industry Requirements

- Behavior of Sulfur during Calcining

- Abatement of SOx emissions in Calciners and Changing Regulatory Environment

- Sulfur in Anodes and Anode Baking

- Anode Production

- Raw Materials and Sulfur Content

- Behavior of Sulfur during Baking

- Sox Formation in the Anode Baking Process and Impact on Anode Quality and Plant Operation (including RTO)

- Abatement of Sox in the Bake Furnace (FTC in Smelters; RTO/Wet Scrubber in Stand-Alone Bake Furnaces)

- Sulfur in Reduction

- Sulfur Balance in Smelter

- Behavior in Pots

- SO2 Capture in Alumina Dry Scrubbing

- SO2 Scrubbing Technologies

INSTRUCTORS

Stephan Broek

Stephan Broek graduated from the Amsterdam University of Applied Sciences with a bachelor’s degree in chemical engineering. He also holds a diploma in process technology from Twente University. Broek is director of Environmental Engineering & technology and part of the Light Metals business unit of Hatch Ltd. Under the Center of Excellence, he and his team of specialists work exclusively on primary aluminum smelter projects worldwide. Broek is recognized in the industry for his knowledge and experience with all types of gas cleaning systems used in smelters around the world. He has been involved in upgrading old GTCs and scrubbers and in the design and construction of new units. He was manager of the contract to install the first two Chinese GTCs in a western smelter. These GTCs have been in operation since 2014 and meet and exceed all requirements. Most recently, Broek has been an advocate of the use of the extended surface filter bags as a tool to extend the operational boundaries of GTCs. He and his team are leading consultants for the implementation of these advanced kinds of filter bags. A third area he and his team work on at any given time, is to help smelters with the emissions projections when potlines are undergoing amperage increases. Hatch has developed a unique smelter emission model that enables the user to investigate an infinite amount of configurations in smelter and to see the impacts on emissions. Broek is also a leader in SPL processing. He is up-to-date with market conditions and advices smelters such as Emirates Global Aluminium, Sohar Aluminium, and Ma’aden Aluminium on their strategies to send SPL to sustainable outlets. Broek has been associated with the aluminum industry for almost 20 years. He is a member of the TMS Aluminum Committee and a regular presenter and speaker at major international conferences such as the TMS annual meeting, Arabal, ICSOBA, and MetalBulletin.

Les Edwards

Les Edwards is chief technology officer at Rain CII Carbon and is responsible for customer technical support and R&D activities related to Rain CII Carbon’s and Ruetgers’ sales of calcined pet coke and coal tar pitch to the aluminum industry. Edwards joined the company in 1998 and works out of the Rain CII Carbon office in Covington, Louisiana. He has a B.S. from the University of Western Australia and an MBA from Tulane University in New Orleans. Prior to joining Rain CII Carbon, Edwards spent 11 years working in the aluminum industry in Australia.

Barry Sadler

Barry Sadler has been involved in the aluminum industry for more than 30 years in a range of positions, but always with a focus on anode carbon technology. He earned his B.S. in metallurgical engineering from Royal Melbourne Institute of Technology in 1982 and Ph.D. in metallurgy from University of Queensland in 1992. Sadler has worked in research, production management, organizational development, and corporate technical management for Comalco/Rio Tinto in Australia and New Zealand for more than 20 years. Since 2002, he has been the principal of Net Carbon Consulting Pty Ltd. Sadler has published widely on anode technology, is a regular lecturer at courses run by the University of Auckland, and has been an invited speaker at a range of conferences and meetings. He was the 2013 editor of TMS’s Light Metals proceedings, and has served as the chair of the TMS Aluminum Committee.

REGISTRATION

Registration for this professional development event is available through the TMS 2017 Annual Meeting & Exhibition Registration Form. Please note that registration for the full TMS Annual Meeting & Exhibition is not required to attend a professional development event. Course materials are included in the registration fee and will be distributed as digital download prior to or after the conclusion of the program as provided by instructors.

Registration Fees:

On or Before January 20, 2017

After January 20, 2017

|

| |

|