TMS 2017 Course Offerings

Full Day Events

Emerging Electronic Interconnect Materials and Processing for Advanced Packaging Technology Workshop

Refractory Linings Used in Aluminum Production

Half-Day Morning Events

Hands On: Interactive Materials Data Visualization and Selection Tools for Research and Teaching Workshop

Hands On: New Demos and Activities to Engage Students in Materials Science and Engineering Workshop

Managing Sulfur in Cokes, Anodes, and Smelter Potline Exhaust Gases Course

Half-Day Afternoon Events

Additive Manufacturing Materials and Processes Workshop

Emerging Technologies that are Poised to Change the Aluminum Industry Workshop

How Carbon Materials are Used in Aluminum Production Workshop—an Introduction for Non-Technologists

Introduction to Atom Probe Tomography Workshop

|

This course has been cancelled for TMS2017.

| How Carbon Materials are used in Aluminum Production Workshop – An Introduction for Non-Technologists |

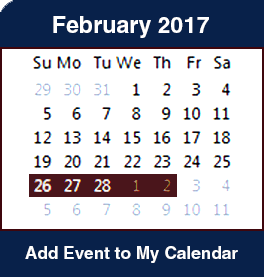

| When | Sunday, February 26, 2017 • 1:00 p.m. to 4:30 p.m. |

| Where | San Diego Convention Center |

| Sponsorship | TMS Light Metals Division (LMD) and Aluminum Committee

Endorsed by the Jacobs Consultancy 16th Annual Petcoke Conference

|

| Instructors | Barry Sadler (Lead Organizer/Instructor), Net Carbon Consulting Pty Ltd., and Kyle Bromilow, R&D Carbon |

| Flyer |

View / Download View / Download |

SCOPE

Industries and organizations involved in the production, supply, procurement, and use of carbon raw materials and the finished anode and cathode electrodes used to make aluminum employ many non-technical staff in a wide range of commercial and management roles. Many of these staff may have never had the chance to learn the basic technology of the carbon materials and products they are involved with every day. This course aims to provide this basic knowledge in a non-technical way. The topics to be covered in the full- day short course include where the various filler coke and binder carbon raw materials and electrodes come from, and how they are manufactured, tested and consumed. Particular attention will be paid to the key properties important to customers. After attending the course, attendees will have a broad understanding of the physical aspects of the value chains for carbon electrodes, and be able to better engage with customers and suppliers.

WHO ATTENDS?

This short course is aimed at non-technical staff involved in the production, supply, procurement, and use of carbon raw materials (e.g., coke and pitch) and the finished anode and cathode electrodes used to make aluminum. The course is also suitable for staff who may be new to the industry and wish to get a technical overview of the use of carbon products in aluminum production.

INSTRUCTOR BIOS

Barry Sadler

Barry Sadler has been involved in the aluminum industry for around 35 years in a range of positions, but always with a focus on anode carbon technology. He has degrees in metallurgy and worked in research, carbon plant production management, organizational development, and corporate technical management for Comalco/Rio Tinto in Australia and New Zealand for more than 20 years. Since 2002, he has been the principal of Net Carbon Consulting Pty Ltd., and provides advice, training, and support to worldwide clients on improving carbon raw material, anode, and carbon plant performance, always maintaining a strong focus on the practical application of statistical thinking and methods. Sadler has published widely on anode technology, is a regular lecturer at courses run by the University of Auckland, and has been an invited speaker at a range of conferences and meetings. He was the editor of TMS 2013 Light Metals proceedings, and has served as the chair of the TMS Aluminum Committee.

Kyle Bromilow

Kyle Bromilow joined R&D Carbon in April 2016 as technical services manager. Prior to this he worked for Bawtry International Carbon in a range of technical management, sales, and R&D roles. He has extensive experience in the production and use of the cathodes and ramming pastes used in aluminum production. In his role with R&D Carbon, Bromilow provides support and carbon testing services with specific emphasis on the production and performance of cathodes and ramming paste, including cathode autopsies and ramming audits. Bromilow has a master’s of science in chemistry from the University of Sheffield and is an active member of TMS.

REGISTRATION

Registration for this professional development event is available through the TMS 2017 Annual Meeting & Exhibition Registration Form. Please note that registration for the full TMS Annual Meeting & Exhibition is not required to attend a professional development event. Course materials are included in the registration fee and will be distributed as digital download prior to or after the conclusion of the program as provided by instructors.

Registration Fees:

On or Before January 20, 2017

After January 20, 2017

|

| |

|