|

Several invited lectures from distinguished and influential members of the materials community are planned throughout the week, including those listed below.

Andrew "Drew" Steigerwald |

Congressional Science and Engineering Fellowship Program

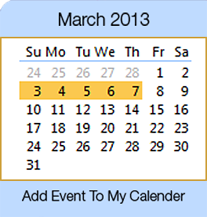

| Date: |

Monday, March 4, 2013, 8:00 a.m. to 9:00 a.m. |

| Location: |

Grand Hyatt Hotel, Presidio C |

| |

| Speaker: |

Andrew "Drew" Steigerwald, 2012-2013 TMS/MRS Congressional Science & Engineering Fellow |

Have you ever considered being a Congressional Fellow? Attend this informational session to learn about The Minerals, Metals & Materials Society and Materials Research Society (TMS/MRS) Congressional Fellowship Program. TMS offers opportunities to learn about the field of science policy by spending a year as a special legislative assistant in the United States Congress in Washington, DC. Fellows serve at all stages of their careers, so make sure to attend and find out about life as a scientist in the U.S. Senate and House of Representatives.

Steigerwald will talk about the many benefits of science fellowships and the importance of scientists’ involvement in policy. Steigerwald’s fellowship placement is in the office of Senator Sherrod Brown working directly with the legislative staff on energy, manufacturing, and tax policy, helping to develop ideas and strategies to implement different policies in the upcoming Congress. There will be ample opportunity for questions and discussion.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

Alex Zunger |

2013 William Hume-Rothery Award Lecture

Lecture Title: "First Principles Alloy Theory – A Retrospective"

| Date: |

Monday, March 4 at 8:40 a.m |

| Location: |

Henry B. Gonzalez Convention Center, Room 205 |

| |

| Speaker: |

Alex Zunger, Professor, University of Colorado, Boulder |

"First Principles Alloy Theory – A Retrospective"

Since Hume-Rothery, Pauling, and Friedel, Alloy Theory has been influenced by electronic structure theory. Whereas Density Functional theory has had, for a long time, a significant impact on our understanding of ordered solids, only in the past two decades has it been combined with statistical mechanics to produce a viable, electronic-structure-based theory of alloys. Zunger will describe his personal view of this development, including the development by his colleagues and collaborators of foundational tools of the trade (total-energy concept and first-principles pseudopotentials), through "first-principles thermodynamics" and computational discovery of new materials, in the areas of metal alloys, semiconductor alloys, and insulator alloys.

Speaker Biography

The winner of the 2013 Acta Materialia Inc. Materials & Society Award (formerly the J. Herbert Hollomon Award), Jeffrey Wadsworth has been president and chief executive officer (CEO) of Battelle Memorial Institute since January 2009.

Battelle is the world’s largest nonprofit research and development organization, executing about $6.5 billion of work annually and employing about 24,500 people. Prior to becoming CEO, Wadsworth led Battelle’s Global Laboratory Operations business, overseeing six major laboratories for the U.S. Department of Energy (DOE), one for the U.S. Department of Homeland Security, and one for the United Kingdom’s Department of Energy and Climate Change. He also led the expansion of Battelle’s operations into China, Japan, Korea, and India and the development of partnerships with the private sector in those nations.

Wadsworth was educated at Sheffield University in England, where he earned both a bachelor’s degree and Ph.D. in Metallurgy. Sheffield also later awarded him a Doctor of Metallurgy degree for his published work, as well as an honorary Doctor of Engineering degree—the university’s highest recognition. Wadsworth came to the United States in 1976 and has worked at Stanford University, Lockheed Missiles and Space Company, and Lawrence Livermore National Laboratory. In 2002, he joined Battelle and served as a member of the White House Transition Planning Office for the U.S. Department of Homeland Security. From 2003 to June 2007, he was director of Oak Ridge National Laboratory, the DOE’s largest multipurpose science laboratory.

A 2000 TMS Fellow, Wadsworth has authored or co-authored nearly 300 scientific papers and one book, and has been granted four U.S. patents. He was elected a member of the U.S. National Academy of Engineering in 2005 and the Chinese Academy of Engineering in 2012. His technical contributions are recognized internationally in the fields of superplasticity of metals and ceramics, refractory metals, high temperature materials, and Damascus and other ancient steels. As a board member of Achieve, Inc. and the Business Higher Education Forum, Wadsworth is committed to leading national efforts to enhance science, technology, engineering and math (STEM) education.

Wadsworth’s recent awards include ASM International’s 2011 Medal for the Advancement of Research, the 2010 Navigator Award from the Potomac Institute for Policy Studies, the 2010 Friendship Award of the State Administration of Foreign Experts Affairs for contributions and dedication to China’s economic construction and social development, the 2009 National Materials Advancement Award from the Federation of Materials Societies, the 2009 TMS/ASM Distinguished Lectureship in Materials & Society, and the 2009 Globe and Anchor Award from the Marine Corps Scholarship Foundation.

|

Donald Sadoway

Antoine Allanore |

Extraction & Processing Division Distinguished Lecturer

Lecture Title: "Towards Sustainable Metal Production by Molten Oxide Electrolysis"

| Date: |

Monday, March 4 at 9:00 a.m |

| Location: |

Henry B. Gonzalez Convention Center, Room 006D |

| |

| Speaker: |

Antoine Allanore, Thomas B. King Assistant Professor of Metallurgy, Massachusetts Institute of Technology, speaking on behalf of Donald Sadoway, John F. Elliott Professor of Materials Chemistry, Massachusetts Institute of Technology |

| |

| Abstract: |

Molten oxide electrolysis (MOE) produces liquid metal and oxygen gas by the electrolytic decomposition of metal oxide feed dissolved in a molten oxide solvent. Since no carbon is used either as reductant or heat source, there are no CO2 emissions from the smelter, and specific energy consumption is lower than current technology. Obviously, the source of electricity for an MOE smelter must be carbon-free as is the practice with aluminum, e.g., hydroelectric or nuclear. With its low capital cost, MOE is economically viable at smaller scale than many of today’s thermochemical technologies. The relevant electrochemistry of the process will be presented along with the materials science behind the oxygen evolving inert anode. |

"Towards Sustainable Metal Production by Molten Oxide Electrolysis"

It has been known that metals having ultra-fine grains (UFGs) produced by severe-plastic deformation processes exhibit unique mechanical properties such as hardening by annealing and softening by deformation in UFG-Al [1]. Although the unique phenomena are associated with the high dislocation density LV (m-2) and high density of grain boundary SV (m-1), there are few quantitative reports about those lattice defects. In the present study, an accumulative roll bonding (ARB) process was used to fabricate the UFG metals. The change in LV, depending on the number of the ARB cycle, was quantified using transmission electron microscopy/scanning transmission electron microscopy (TEM/STEM) and electrical resistivity measurements at 77 K. As a result, it was revealed that LV is almost constant for all ARB processed metals, with values of around 1.0×1014m-2 and 5.0×1014m-2 for UFG-Al and UFG-Cu, respectively.

|

Vincenzo Palermo |

Federation of European Materials Societies Young Leader International Scholar

Lecture Title: "Not a Molecule, Not a Polymer, Not a Substrate . . . the Many Faces of Graphene as Chemical Platform"

| Date: |

Monday, March 4 at 2:35 p.m. |

| Location: |

Henry B. Gonzalez Convention Center, Room 201 |

| |

| Speaker: |

Vincenzo Palermo, Institute for Organic Synthesis and Photoreactivity, CNR - National Research Council of Italy |

"Not a Molecule, Not a Polymer, Not a Substrate . . . the Many Faces of Graphene as Chemical Platform"

What is, exactly, graphene?

While we often describe graphene with many superlative adjectives, it is difficult to force this (superlative) material within a single chemical class. Graphene typical size is atomistic in one dimension of space, and mesoscopic in the others two. This provides graphene with several, somehow contrasting properties. Graphene can be can be patterned, etched and coated as a substrate. Though, it can also be processed in solution and chemically functionalized, as a molecule. It could be considered a polymer, obtained by bottom-up assembly of carbon atoms, but it can be obtained from top-down exfoliation of graphite (a mineral) as well. It is not a nano-object, as fullerenes or nanotubes, because it does not have a well-defined shape; conversely, it is a large, highly anisotropic, very flexible object, which can have different shapes and be folded, rolled or bent to high extents.

In this presentation, we will discuss the state of the art and possible applications of graphene in its broader sense with a particular focus on how its "chemical" properties, rather than its well-known electrical ones, can be exploited to develop original science, innovative materials and new technological applications.

|

Horst Hahn |

Institute of Metals/Robert Franklin Mehl Lecture

Lecture Title: "Tunable Nanostructures and Printed Electronics"

| Date: |

Tuesday, March 5, 2013 at 9:05 a.m. |

| Location: |

Henry B. Gonzalez Convention Center, Room 201 |

| |

| Speaker: |

Horst Hahn, Karlsruhe Institute of Technology |

"Tunable Nanostructures and Printed Electronics"

The properties of materials are typically controlled by their microstructure. As a consequence, the properties cannot be altered reversibly. In contrast, gating using electrical charges allows for the reversible change of properties and has an enormous potential for applications. In general, charges can be applied at interfaces between an oxide (dielectric gating) or an electrolyte (electrochemical gating) and the material. This can be applied for the reversible change of mechanical, electrical and magnetic properties of nanostructures. In a similar way, electrochemical gating can be applied to printed field-effect transistors based on inorganic oxide nanoparticles. The basic principles of tunable nanostructures will be discussed, as well as the application of the electrochemical gating concept for printed electronics. The technical performance, such as field effect mobility, device speed, temperature range, etc. will be highlighted.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

Maurits Van Camp |

Extraction & Processing Division/Materials Processing & Manufacturing

Division Joint Luncheon Lecture

Lecture Title: "Sustainability: A Paradigm Shift for Metals?"

Note: Tickets are required for this event. Register for the luncheon on the TMS2013 Conference Registration form.

| Date: |

Tuesday, March 5 at Noon |

| Location: |

Grand Hyatt Hotel, Texas Ballroom C |

| |

| Speaker: |

Maurits Van Camp, Director of the Recycling & Extraction Technologies Platform at Umicore Group Research and Development |

"Sustainability: A Paradigm Shift for Metals?"

The global demand for technology metals has drastically increased. This will further accelerate as a result of the introduction of green and high-tech technologies. To secure a reliable and sustainable supply of these metals, innovative solutions need to be developed along the entire value chain. This requires a system-wide approach focusing on sustainable mining methods, substitution of critical metals, and recovery of metals from secondary sources. Even more than today, the walls between different research areas, metal and product sectors, industries, corporations and SMEs, industry and policy makers, countries etc. need to be removed.

Sustainable solutions hinge on the development of technologies that simultaneously seek gains in economic, social, and environmental aspects. When applying this to metal recovery from complex sources, coupling between metals imposes certain trade-offs. This balancing issue is explained by means of the periodic table of elements. Strategies to overcome related metallurgical challenges are illustrated in Umicore’s flowsheet. The latter is designed to recover metals in low concentrations from intermediates and end-of-life products with a high recovery yield and minimal emissions and waste.

Another key element facilitating the transition toward sustainability is cross-border and cross-sectoral collaboration. The need to enhance connectivity is recognized on the global as well as regional level. The EU-Japan-US trilateral roundtable on critical raw materials brings together different stakeholders from across the world. In Europe, the "Innovation Union" flagship initiative within the Horizon 2020 strategy aims to foster innovation by adopting a joint stakeholders approach. In the U.S., the aspect of interconnection is implemented through the formation of Energy Innovation Hubs, among others. Active engagement of the metals and materials industry in these initiatives is key to driving the paradigm shift needed to achieve a sustainable society.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

Julia Greer |

Young Leader Tutorial Luncheon Lecture

Presentation Title: "A Scientist, a Parent, a Teacher, a Mentor… How to Balance it All?"

All TMS2013 attendees are welcome to attend this lecture. Optional boxed lunches can be ordered for this event through the TMS2013 Conference Registration form.

| Date: |

Tuesday, March 5 at Noon |

| Location: |

Grand Hyatt Hotel, Texas Ballroom D |

| |

| Speaker: |

Julia Greer, Assistant Professor of Materials Science and Mechanics, Caltech |

"A Scientist, a Parent, a Teacher, a Mentor… How to Balance it All?"

In my Young Leaders Tutorial Luncheon Lecture, I would like to focus on the issues of work/life balance as a woman in academia and on how to balance the professional and personal activities without feeling overwhelmed.

"Would you be willing to participate in a panel discussion on work/life balance at Meeting/Conference/Workshop X please?" is the question I hear quite often – maybe because I am a faculty advisor to Women Mentoring Women and Society of Women Engineers at Caltech, or maybe because there aren’t enough women in scientific/engineering academia, or maybe because people see me roller blading on campus with two kids in the stroller on the way to work. Whatever the reason, I have been thinking about these issues for quite some time now – whether it is possible to strike a meaningful and satisfying balance between one’s professional and personal "selves." In all honesty, there are days (nights) where I feel like I don’t ever stop working. Now that I am a Mom of two little girls (one is four and another one is almost two), trying to set up a work-life balance has been more challenging than I had ever imagined. Yet it is of key importance as I find that spending quality time with my children makes me a better scientist and intense scientific pursuit facilitates better parenting. In this lecture, I will focus on discussing the issues associated with trying to survive in the world where career, family, and hobbies simultaneously require 100% of one’s attention. I will provide examples of effective and ineffective situations, statistical data, and bring to light some of the perhaps surprising consequences of neglecting to find one’s internal balance.

|

Yoji Miyajima |

Japan Institute of Metals Young Leader International Scholar

Lecture Title: "Quantification of Lattice Defects in Severe-Plastic Deformed Metals"

| Date: |

Wednesday, March 6 at 11:40 a.m. |

| Location: |

Henry B. Gonzalez Convention Center, Room 201B |

| |

| Speaker: |

Yoji Miyajima, Interdisciplinary Graduate School of Science and Engineering, Tokyo Institute of Technology |

"Quantification of Lattice Defects in Severe-Plastic Deformed Metals"

It has been known that metals having ultra-fine grains (UFGs) produced by severe-plastic deformation processes exhibit unique mechanical properties such as hardening by annealing and softening by deformation in UFG-Al [1]. Although the unique phenomena are associated with the high dislocation density LV (m-2) and high density of grain boundary SV (m-1), there are few quantitative reports about those lattice defects. In the present study, an accumulative roll bonding (ARB) process was used to fabricate the UFG metals. The change in LV, depending on the number of the ARB cycle, was quantified using transmission electron microscopy/scanning transmission electron microscopy (TEM/STEM) and electrical resistivity measurements at 77 K. As a result, it was revealed that LV is almost constant for all ARB processed metals, with values of around 1.0×1014m-2 and 5.0×1014m-2 for UFG-Al and UFG-Cu, respectively.

|

John Mitchell |

Light Metals Division Luncheon

Lecture Title: "Lithium: Solving Global Energy Issues"

Note: Tickets are required for this event. Register for the luncheon on the TMS2013 Conference Registration form.

| Date: |

Wednesday, March 6 at Noon |

| Location: |

Grand Hyatt Hotel, Texas Ballroom C |

| |

| Speaker: |

John Mitchell, President, North America, Rockwood Lithium |

"Lithium: Solving Global Energy Issues"

Lithium, the lightest metal in existence, has taken on a new importance in global energy markets. As nations search for ways to become more energy efficient and self-reliant, the production and use of electricity is now a greater focus. Lithium ion batteries provide a cost effective and reliable storage method for electrical energy today. While the battery industry and research institutions remain highly fragmented in approach, they all race to improve the same battery performance metrics. Solving some of these metrics could lead to the next global growth market. However, lithium’s contribution toward solving energy needs do not begin and end with batteries. The growing use of aluminum lithium alloys in aerospace for weight reduction and the addition of lithium salts to save energy when operating melt furnaces are among other energy saving applications for lithium. While elemental lithium is found everywhere, factors like economics and geopolitical dynamics limit the focus of major lithium producers to source raw material from only a few places around the world. However, unlike other key global resources, lithium can be part of the energy solution for a much longer duration because it lends itself to recycling. This presenter will discuss the lithium industry, key growth markets, technology trends and other outside influences on the broader use of lithium when solving global energy issues.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

Leon Prentice |

Vittorio de Nora Prize for Environmental Improvements in Metallurgical Industries Lecture

Lecture Title: "It Is Rocket Science: The Engineering and Impact of Carbothermal Magnesium Technology"

| Date: |

Wednesday, March 6 at 4:15 p.m. |

| Location: |

Henry B. Gonzalez Convention Center, Room 006C |

| |

| Speaker: |

Leon Prentice, Senior Research Engineer, CSIRO Process Science and Engineering |

"It Is Rocket Science: The Engineering and Impact of Carbothermal Magnesium Technology"

Carbon is regularly used as a reductant for the production of many metals due to its simplicity, efficiency, and ease of use. For light metals the thermodynamics – and engineering – are more complex. The production of magnesium by carbothermal reduction has been a goal for nearly a century, yet significant practical challenges have made its operation uneconomic. A multi-disciplinary team from Australia’s national research organisation, CSIRO, has proven the technology at laboratory scale and demonstrated the operation of supersonic ‘shock quenching.’ This technology, called MagSonic™, is likely to be cost-competitive with existing processes while reducing energy consumption by up to 50% and environmental impact by up to 85%. Further advantages can be gained from renewable energy and carbon sources. This presentation will discuss the engineering challenges overcome in the development of MagSonic™ technology so far, and its potential to change the production and use of magnesium around the world.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

Sumit Goenka |

2013 Shri Ram Arora Award Lecture

Lecture Title: "Antibacterial Nanosized Silver Substituted Hydroxyapatite with Enhanced Mechanical Properties"

| Date: |

Wednesday, March 6 at 4:45 p.m. |

| Location: |

Henry B. Gonzalez Convention Center, Room 214C |

| |

| Speaker: |

Sumit Goenka, Department of Materials Science & Engineering, Carnegie Mellon University, and Department of Metallurgy & Materials Engineering, Visvesvaraya National Institute of Technology |

Antibacterial Nanosized Silver Substituted Hydroxyapatite with Enhanced Mechanical Properties

Among the bioactive materials that have been used for orthopedic biomaterials design, hydroxyapatite [Ca10(PO4)6(OH)2] is a good candidate owing to its biocompatibility, osteoconductive properties and its presence in natural hard tissue. Poor mechanical properties such as brittleness, low tensile strength and poor machinability restrict their application. In this work we fabricated silver substituted hydroxyapatite [Ca10-xAgx(PO4)6(OH)2] with enhanced mechanical and antibacterial properties.

Speaker Biography

Maurits Van Camp is currently director of the recycling & extraction technologies platform at Umicore Group Research and Development in Olen, Belgium. Van Camp graduated from the K.U.Leuven, Belgium, as a material science engineer in 1979 and received his masters in extractive metallurgy from the University of Utah, USA, in 1981. He has over 30 years of research experience in the field of extractive metallurgy. His prime focus has been in realizing breakthrough developments for closing the loop for non-ferrous metals: Pb-Cu-Zn-Ni-Co-As-Se-Te-Bi-Sb-Sn-Ag-Au-In-Ge-PGMs and rare earth metals. He has been instrumental in the make-over of Umicore Precious Metals Refining through his involvement in the introduction of breakthrough technologies such as the Cu smelter, the precious metals concentration plant, and the rechargeable battery recycling process. Within his research, the minimalist approach of Prof. Jaikumar has been the underlying philosophy for developing, realizing, and implementing breakthrough developments.

|

|