|

DIVISION LUNCHEON LECTURES

Because the following events include a catered lunch, there is a $35 cost to attend. Tickets can be purchased through the Meeting Registration form.

Michael J. Mills

|

Structural Materials Division (SMD) Luncheon Lecture

Lecture Title: "Importance of Advanced Characterization Techniques for Understanding of Deformation Behavior in Structural Materials"

|

Michael J. Mills, Taine G. McDougal Professor of Engineering, The Ohio State University

|

|

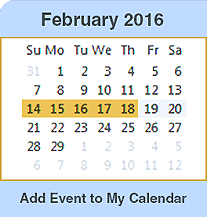

Monday, February 15

|

|

Noon to 2:00 p.m.

|

| Omni Nashville Hotel, Legends E&F |

|

$35 per person (Tickets can be purchased through the Meeting Registration form)

|

|

|

Abstract

The international initiative on Integrated Computational Materials Engineering holds great promise for accelerating the insertion of new materials in high performance structural applications. Achieving this aim relies upon the fidelity of materials models and their ability to capture the connectivity between processing, microstructure, and performance. This presentation will focus on advancements in our ability to characterize deformation mechanisms at finer length-scales—from atomic to grain-level behavior. For instance, in the Ni-base superalloys, a surprising

variety of governing mechanisms are observed as a function of microstructure and deformation condition. In particular, at elevated temperature, the strain rate and temperature dependence of deformation depends on the onset of several deformation mechanisms that are distinct from the "classic" APB shearing process that dominates at lower temperature. Using electron-microscopy-based techniques, new insights into the governing deformation mechanisms in several important structural materials are being developed. Another example to be discussed are the high-temperature

shape-memory alloys for which the interplay between dislocation plasticity and martensitic transformation determines the macroscopic behavior that is highly desirable for new actuator

applications. The important role played by characterization in motivating modeling at several important length-scales (including atomistic, phase

field and crystal plasticity) will also be discussed.

About the Presenter

David L. Bourell is the Temple Foundation Professor of Mechanical Engineering at The University of Texas at Austin. He is currently Director of the Laboratory for Freeform Fabrication. Bourell's areas of research include particulate processing with emphasis on sintering kinetics and densification, and materials issues associated with Laser Sintering (LS). He holds 9 primary patents dealing with materials innovations in LS dating back to 1990 and has published over 200 papers in journals, conference proceedings, and book chapters.

Bourell is a Fellow of ASM International and TMS, and he is also a lifetime member of TMS. He was elected an Associate Member of the CIRP in 2013. In 2009, he received the TMS Materials Processing and Manufacturing Division Distinguished Scientist/Engineer Award. He has received two major conference career awards in additive manufacturing: the SFF Symposium FAME Award and the Portuguese VRAP Career Educator Award.

Bourell is a leading expert in advanced materials for Laser Sintering, having worked in this area since 1988. He was the lead author on the original materials patent for LS technology. Issuing in 1990, this patent has been cited by over 170 other patents, and it represents the original intellectual property for mixed and coated powders for LS, including binders. Since 1995, he has chaired the organizing committee for the Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. This meeting is a leading research conference on additive manufacturing.

|

David L. Bourell

|

Extraction & Processing Division (EPD)/Materials Processing & Manufacturing Division (MPMD) Joint Luncheon Lecture

Lecture Title: "Additive Manufacturing or 3D Printing: Origins, Applications and Future Possibilities"

|

David L. Bourell, Temple Foundation Professor, The University of Texas at Austin

|

|

Tuesday, February 16

|

|

Noon to 2:00 p.m.

|

| Omni Nashville Hotel, Legends E&F |

|

$35 per person (Tickets can be purchased through the Meeting Registration form)

|

|

|

Abstract

The history and future will be presented for modern Additive Manufacturing (AM), also known as 3D Printing. The technology, divided into seven categories by ASTM, dates to the 1980s, although precursor processes and AM "prehistory" date to the 1950s and the previous century, respectively. A rationale will be presented for the use of AM processes in lieu of conventional manufacturing processes. Two requirements for parts under consideration for AM are complex geometry and low production runs. Current sectors using AM illustrate the results. A survey of materials for AM will be provided. Some consideration will be presented respecting where AM technology is headed.

Speaker Biography

David L. Bourell is the Temple Foundation Professor of Mechanical Engineering at The University of Texas at Austin. He is currently Director of the Laboratory for Freeform Fabrication. Bourell's areas of research include particulate processing with emphasis on sintering kinetics and densification, and materials issues associated with Laser Sintering (LS). He holds nine primary patents dealing with materials innovations in LS dating back to 1990 and has published over 200 papers in journals, conference proceedings, and book chapters.

Bourell is a Fellow of ASM International and TMS, and he is also a lifetime member of TMS. He was elected an Associate Member of the CIRP in 2013. In 2009, he received the TMS Materials Processing and Manufacturing Division Distinguished Scientist/Engineer Award. He has received two major conference career awards in additive manufacturing: the SFF Symposium FAME Award and the Portuguese VRAP Career Educator Award.

Bourell is a leading expert in advanced materials for Laser Sintering, having worked in this area since 1988. He was the lead author on the original materials patent for LS technology. Issuing in 1990, this patent has been cited by over 170 other patents, and it represents the original intellectual property for mixed and coated powders for LS, including binders. Since 1995, he has chaired the organizing committee for the Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference. This meeting is a leading research conference on additive manufacturing.

|

Gregory R.

Wittbecker

|

Light Metals Division (LMD) Luncheon Lecture

Lecture Title: "2016 Aluminum

Fundamentals: A Producer’s View"

|

Gregory R. Wittbecker, Vice President–Industry Analysis,

Alcoa Global Primary Products

|

|

Wednesday, February 17

|

|

Noon to 2:00 p.m.

|

| Omni Nashville Hotel, Legends E&F |

|

$35 per person (Tickets can be purchased through the Meeting Registration form)

|

|

|

Abstract

The U.S. government has launched a new National Network of Manufacturing Institutes designed to be a public-private partnership aimed at improving domestic manufacturing competitiveness. Four of these institutes have been awarded and several more are planned. Each institute is focused on a particular advanced manufacturing technology and will serve as the bridge between basic research and final product commercialization. The institutes are designed to link a network of universities and national/federal laboratories with companies in a targeted industrial sector. The companies range from small and medium enterprises to large suppliers and OEMs.

This talk will describe how these institutes are operating using the American Lightweight Materials Manufacturing Innovation Institute (ALMMII) as an example. ALMMII is focused on the land, sea, and air transportation sectors, both commercial and defense. The mission is to provide technology solutions that will make the transport of people and goods more sustainable in terms of energy, the environment, safety, and affordability. Reducing weight is a key enabler for meeting these challenges as well as increasing payload and improving performance. In addition to developing new manufacturing processes, ALMMII is also working to develop a prepared and eager metals processing workforce.

Speaker Biography

Martin Bates is President, Strategy, Energy & Development, Alcoa Inc., Global Primary Products in Pittsburgh, Pennsylvania. Bates leads Alcoa’s upstream portfolio strategy and management, including Alcoa’s energy business unit. His responsibilities include setting and executing the global upstream portfolio asset strategies. He is also responsible for Alcoa Energy and Transformation business units and Alcoa’s research and development investments in new smelting process technologies. He joined Alcoa's Global Primary Products (GPP) team in 2010 as Vice President of Strategy and Development. The GPP business group includes the company's mining, refining, smelting, and casting business units.

Bates joined Alcoa in 2005 as Director of Corporate Development with responsibility for strategy and analysis. In 2007, he worked with Alcoa’s Executive Council, the team of senior leaders that set strategic direction for the company, to begin the development of Alcoa’s Three Strategic Priorities—profitable growth, disciplined execution, and the Alcoa Advantage—and helped establish Alcoa’s internal management consulting organization in 2008.

Bates began his career with General Electric as a manufacturing engineer, and later held roles in engineering design and program management with Lockheed Martin and strategy consulting with McKinsey and Company. He holds bachelor's degrees in Mechanical Engineering and Liberal Arts from Pennsylvania State University and an MBA from University of Virginia's Darden School of Business.

|

AWARD LECTURES

All meeting attendees are welcome to attend the following featured lectures, delivered by award-winning presenters.

Markus A. Reuter |

Extraction & Processing Division Distinguished Lecturer

Lecture Title: "Digitalizing the Circular Economy—System-Integrated-Material-Production"

|

Markus A. Reuter, Director, Helmholtz Institute Freiberg for Resource Technology, Helmholtz-Zentrum Dresden-Rossendorf

|

|

Tuesday, February 16

|

|

9:30 a.m.

|

|

Music City Center, Room 104B

|

|

Part of the REWAS 2016 Plenary Session: Materials Matter: Deriving Value from Resource Recovery at Multiple Materials Scales

|

Abstract

Metals have always been a pillar of society—presently more so than ever, as they are key to enabling our sustainability aspirations. The complex Web of Metals (WoM) is the crucial basis for enabling a sustainable Circular Economy (CE) society.

Digitalization and quantification of the WoM—or Internet-of-Metallurgical-Things (IoMT)—are keys to driving CE innovation. Examples of specialized technology and flow sheet needs are presented with consideration given to a "whole of chain" or Systems-Integrated-Metal-Production (SIMP) approach. Examples enabling SIMP include: system, metallurgical process and reactor simulation (e.g. CFD, thermodynamics, flowsheeting, LCA), big data analysis (AI, black box techniques), process control, and Design for Recycling/Sustainability.

Also outlined are the challenges facing legislators who need to consider the balance between providing our societal sustainability needs with key baseline technology infrastructure requirements for economically viable valuable metals extraction from resources flowing within society.

Digitalization enables the IoMT of a CE.

Speaker Biography

Markus A. Reuter is Director of the Helmholtz Institute Freiberg for Resource Technology at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) in Freiberg, Germany. In this role, Reuter researches the "Internet of Things," that is, into the recycling of metallic raw materials within a material and energy-efficient Circular Economy 4.0.

Reuter is also an adjunct professor at Aalto University in Finland and a guest professor at Central South University in China. Prior to joining HZDR in 2015, Reuter worked for Outotec (Ausmelt) in Australia and Finland for nine years. He has also previously worked as leader of the furnace control group for Mintek in South Africa and as a process metallurgist for Anglo American Corporation in South Africa.

He holds a doctorate in engineering and a Ph.D. from Stellenbosch University in South Africa and a Dr. habil. degree from RWTH Aachen in Germany. In 2015, he was awarded an honorary doctorate from the Université de Liège in Belgium.

|

Brent Fultz |

2016 William Hume-Rothery Award Lecture

Lecture Title: "The Origin of Entropy in Materials"

|

Brent Fultz, Rawn Professor of Materials Science and Applied Physics, California Institute of Technology

|

|

Monday, February 15

|

|

8:40 a.m.

|

|

Music City Center, Room 107A

|

|

|

Abstract

Most of the entropy of materials comes from vibrations of atoms—vibrational entropy is typically an order-of-magnitude larger than other sources, such as configurational entropy. Historically, differences in vibrational entropy between different phases have been subtle and troublesome to assess. Some trends and rules emerged over the years, such as how the formation of short, stiff bonds tends to reduce the vibrational entropy. The situation at high temperatures is complicated, but arguably more important for materials processing. At elevated temperatures, the harmonic and quasiharmonic approximations are unreliable. All materials have phonon-phonon interactions at high temperatures because interatomic potentials are not perfectly harmonic. Metals also have electron-phonon interactions, and magnon-phonon interactions are important for iron, for example. For less-complicated materials, it is exciting that we can now measure or calculate accurately the different parts of entropy at elevated temperatures, even when the material is far from a harmonic solid.

Speaker Biography

Brent Fultz received his undergraduate degree from the Massachusetts Institute of Technology (MIT) and his Ph.D. from the University of California, Berkeley in 1982. He has authored or co-authored well over 350 publications, including two textbooks: Transmission Electron Microscopy and Diffractometry of Materials (Springer, 4th ed.) by B. Fultz and J.M. Howe and Phase Transitions in Materials (Cambridge, 2014) by B. Fultz. Fultz was Principal Investigator for constructing the ARCS neutron spectrometer at the Spallation Neutron Source, and was P.I. for the software project to develop Distributed Data Analysis for Neutron Scattering Experiments (DANSE). Awards include a Jacob Wallenberg Foundation Scholarship, Presidential Young Investigator Award, and the 2010 Distinguished Scientist/Engineer Award from the former TMS Electronic Magnetic & Photonic Materials Division (now the Functional Materials Division).

About 30 years ago, Fultz's group began to measure the differences of vibrational entropies of materials. This led to studies of phonon spectra by inelastic neutron scattering, which gave more detail about how the vibrational entropy depends on atomic structure and bonding. [For a review, see Prog. Mater. Sci. 55, 247 (2010).] Especially for thermodynamics at elevated temperatures, methods of ab initio molecular dynamics have both augmented the experimental work with inelastic scattering, and have proved powerful in their own right.

Fultz's group also studies materials that store lithium and hydrogen, with emphasis on the thermodynamics of lithiation and hydriding reactions. Present topics include the effects of surface nanostructures on the adsorption of gases, and the effects of microstructure on the performance of metal hydrides. Recent work has used pressure and temperature to study the hopping dynamics of polarons in battery cathode materials, and how polarons interact with lithium ions.

|

Elif Ertekin |

Young Professional Tutorial Luncheon Lecture

|

Tuesday, February 16

|

|

Noon to 2:00 p.m.

|

|

Omni Nashville Hotel, Legends D

|

| |

|

Elif Ertekin, University of Illinois

|

|

"Introducing Innovations in Teaching While Staying on the Research Track"

|

|

|

Abstract

In research university settings, as faculty we are responsible for being effective teachers and educators, as well as leading and overseeing a world-class research program. Often, it is assumed that if one is to excel at one of these, it is not possible to excel at the other. In this Young Leaders Tutorial Luncheon, I would like to challenge this idea. I now firmly believe that the best researchers are also the best teachers, and the best teachers are also the best researchers. The two have a beautifully complementary nature: while research often forces us to think deeply and carefully about a specific research question, teaching helps keep us focused on the big picture.

Drawing from my personal experiences, I will present a discussion on how I learned (and continue to learn) to introduce innovations in the classroom while staying on the research track. I will give some examples of what worked (and what didn’t) and how it is possible not only to achieve balance, but also how to use one to improve the other.

Speaker Biography

Elif Ertekin received her Ph.D. in Materials Science and Engineering from the University of California at Berkeley in 2006, and was a post-doctoral researcher at the Berkeley Nanosciences and Nanotechnology Institute from 2007-2009 and in the Department of Materials Science and Engineering at the Massachusetts Institute of Technology from 2009-2011. Since 2011, she has been an Assistant Professor in the Department of Mechanical Science and Engineering at the University of Illinois at Urbana-Champaign. Ertekin’s research focuses on the application of computational modeling and simulation methods ranging from atomistic first-principles to continuum, to understand, predict, and design new complex materials and materials systems with a focus on sustainable energy applications such as photovoltaics, photocatalysis, and thermoelectrics. The guiding objective behind her work is linking structure at the scale of atoms and electrons, to underlying physical phenomena and mechanisms, to resultant properties and functionality. She was recently named as a recipient of the 2015 College of Engineering Research Award from the University of Illinois.

|

Michael D. Sangid |

|

Michael D. Sangid, School of Aeronautics and Astronautics, Purdue University

|

|

"Accentuating the ‘I’ in ICME"

|

|

|

Abstract

Integrated Materials Computational Engineering (ICME) is quietly revolutionizing materials science. The coordinated efforts of national ICME initiatives aim to deliver the required infrastructure and training to accelerate innovation, discovery, development, validation, and use of advanced materials and manufacturing processes as an integral part of next-generation multi-disciplinary design with a focus on designing for affordability. A primary barrier to the widespread deployment of ICME efforts is the integration of these practices within the design systems, structural analysis, and manufacturing communities. We are past the days of doing research and throwing it over the wall. This luncheon will serve as an open discussion on opportunities to share our materials knowledge, research, and tools with a wider audience, including engineers from other disciplines representing design, structures, manufacturing, and optimization.

Speaker Biography

Michael D. Sangid received his B.S. (2002) and M.S. (2005) in Mechanical Engineering from the University of Illinois at Urbana-Champaign (UIUC). After earning his Master’s degree, Sangid spent two years working in Indianapolis, Indiana, for Rolls-Royce Corporation, specializing in material characterization, fatigue, fracture, and creep of high-temperature aerospace materials before resuming his education in 2007. He received his Ph.D. in Mechanical Engineering from UIUC in 2010 and continued as a post-doctoral associate. In the spring of 2012, Sangid started as an assistant professor at Purdue University in the School of Aeronautics and Astronautics with a courtesy appointment in Materials Engineering, where he continues his work on building computational materials models for failure of structural materials and conducting in situ experiments upon deformation for measuring the spatial strain evolution with respect to the material’s microstructure. He is a recipient of the TMS Young Leaders Award, the ASME Orr Award for contributions in Fatigue and Fracture, and the AFOSR, ONR, and DARPA Young Investigator/Faculty Awards.

|

Henry Proudhon |

Federation of European Materials Societies (FEMS) International Scholar

Lecture Title: "Finite Element Simulations of Short Fatigue Crack Propagation in Three Dimensional Microstructures Obtained by X-ray Tomography"

|

Henry Proudhon, Centre des Matériaux, Mines ParisTech

|

|

Monday, February 15

|

|

2:00 p.m.

|

|

Music City Center, Room 213

|

|

Presented as part of the Fatigue in Materials: Fundamentals, Multiscale Modeling and Prevention Symposium

|

Abstract

Combining in situ fatigue loading with absorption and diffraction contrast tomography, unique data sets can now be obtained to study the effect of the local microstructure on the very first stages of fatigue crack propagation. Crystal plasticity finite element simulations can now advantageously take experimental data as input to study the physical mechanisms at work. Two situations will be presented. First, the initiation of fatigue cracks on second phase particles in a commercial Al-Cu-Li alloy via 3D finite element calculations are compared to experimental observations. A criterion to assess if the crack will grow crystallographically is proposed. Second, the growth of a short fatigue crack in a beta-titanium polycrystalline sample imaged by X-ray tomography is simulated. The model uses a damage indicator to assess the local crack growth rate and direction; remeshing routines are used to achieve propagation over several grains and the results are compared to the tomographic experiment.

Speaker Biography

Henry Proudhon is from the Centre des Matériaux, Mines ParisTech in Evry France. Proudhon’s research addresses challenging problems in materials science, such as short cracks propagation (fatigue), plasticity in polycrystalline materials, and solid damage at contacts (fretting)

|

Motomichi Koyama |

Japan Institute of Metals International Scholar

Lecture Title: "Effective Utilization of ε-Martensite in Fe-High Mn Austenitic Steels: Aspects of Deformation-Induced Reverse Transformation"

|

Motomichi Koyama, Department of Mechanical Engineering, Kyushu University

|

|

Thursday, February 18

|

|

9:40 a.m.

|

|

Music City Center, Room 107

|

|

|

Abstractε-martensite in high Mn austenitic steels has been reported to cause brittle cracking, deteriorating mechanical properties. 1 However, in some specific conditions, ε-martensite plays crucial roles on improvement of low-cycle fatigue resistance, 2 uniform elongation, 3 and yield/tensile strength. 4 A key phenomenon to positively utilize ε-martensite is deformation-induced reverse transformation from ε-martensite to austenite. For instance, reversible deformation-induced ε-martensitic transformation like twinning/detwinning supresses damage accumulation during low-cycle fatigue, drastically improves fatigue life. 2 Furthermore, reversely-transformable pre-existing ε-martensite increases yield/tensile strength without any deterioration of elongation. 4 These phenomena can be interpreted by thermodynamics and crystallographic similarity to mechanical twinning.

References

- M. Koyama, T. Sawaguchi, and K. Tsuzaki, Metall. Mater. Trans. A 2012, vol. 43, pp. 4063-4074.

- T. Sawaguchi, L.G. Bujoreanu, T. Kikuchi, K. Ogawa, M. Koyama, and M. Murakami, Scripta Mater 2008, vol. 59, pp. 826-829.

- M. Koyama, T. Sawaguchi, and K. Tsuzaki, Mater Trans 2015, vol. 56, pp. 819-825.

- M. Koyama, T. Sawaguchi, and K. Tsuzaki, Mater. Sci. Eng. A 2012, vol. 556, pp. 331-336.

Speaker Biography

Motomichi Koyama has been an assistant professor at Kyushu University since 2013. From 2012 to 2013, he was a senior researcher at Max Planck Institute fur Eisenforschung. He received his Ph.D. from Tsukuba University in March 2012. His research is on effects of martensitic transformation, deformation twinning, and strain aging on fatigue crack growth, hydrogen embrittlement, and work hardening.

|

|